We use cookies to make your experience better.

TrucknTow takes your security and privacy seriously. To learn more about the data we collect, please review our Privacy Policy.

Free Ground Shipping On Everything. No Exceptions, No Surprises At Checkout.

| How to select and order your Certified Alloy Lifting Sling: |

|

|

1. Determine the number of legs and the type of hooks that your

lifting application requires. Click on the corresponding icon in the chain slings main

page. 2. Determine the maximum weight and size of the load to be lifted. 3. Determine the chain size and attachment style that your application requires according to the working load limit chart provided within each chain sling category. Be sure to consider the effect of lifting angle when selecting the reach (leg length). All reach measurements are bearing to bearing. 4. Click on the part number corresponding with the weight, chain size, and attachment required for your application. You'll find a list of available lengths to add to your cart. NOTE: If you don't see the chain sling combination you need, call 888.918.8150, and we'll be happy to assist you. Be sure to specify the sling type, size and reach when ordering. |

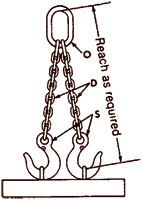

Please use the four letter designation to describe the sling type. The first two letters describe the number of legs, the third letter describes the type of master link, and the fourth letter describes the type of hooks. For example, the sling pictured is a YDOS because it is Double legged, has an Oblong master link, and has Sling hooks. If you wanted this sling made from 3/4” alloy with 10’ of reach, you would simply order a 3/4” x 10’ YDOS. Other letters used to designate types of slings are:

| First Two Letters (Sling Type) | Third Letter (Master Link) | Fourth letter (Hook Type) |

| YS = Single chain sling | O = Oblong master link | S = Sling hooks |

| YD = Double leg chain sling | P = Pear master link | G = Grab hooks |

| YT = Triple leg chain sling | R = Round master ring | F = Foundry hooks |

| YQ = Quadruple leg chain sling | L = Latchlok hooks | |

| YC = Choker sling | X = Special attachments |

|

All of our alloy lifting slings include a metal identification tag, and are accompanied by a pull test certificate for your files. |

Care: Always make sure that your chains are properly stored and maintained. Adhering to

the following guide lines will prolong the life and strength of your chains.

1.

Store chains on an A-frame in a clean, dry place.

2. Oil chains before extended

storage.

3. Do not heat alloy chain. Heating alters the thermal treatment that has

been applied to the chain.

4. Do not plate or change the surface finish of the chain

without contacting your Vulcan representative.

Use: To protect operators and prolong chain life, observe the following precautions when

using alloy lifting slings.

1. Before each use, inspect the chain and attachments

for damage and defects as described below.

2. Never exceed the Working Load

Limit.

3. Avoid any of the following situations, as they will decrease the working

load limit of your chain:

a. Acceleration in rate of load application (shock loading).

b.

Variation in the lifting angle of the sling. As the lifting angle decreases, the working load decreases

dramatically. (Charts are available on chain sling category pages)

c. Twisting, knotting or kinking

of the sling will cause uneven wear and drastic reduction in working load limit.

4.

Center load in hook(s). Latches are not designed to support the weight of a load.

5.

Avoid sudden jerks when lifting or lowering.

6. Balance all loads. Uneven loading

will reduce working load limit.

7. Use wear pads around sharp

corners.

8. Never drop load on chains.

9. For overhead lifting,

use only certified alloy chain and attachments.

Inspection

It is important to inspect chains and attachments before each use. OSHA

requires that chains and attachments be inspected and certified on an annual basis. Vulcan Chain offers

annual inspections to all of its alloy customers. If you are inspecting your own chain, remove it from

service immediately if any of the following conditions exist: Twists or bends of a link, Nicks or Gouges

in a link, Excessive wear, Stretch, or Distorted or damaged master links, coupling links or attachments.